Choosing the right knife steel isn’t just about specs on a chart; it’s about performance when it matters. I’ve put blades through hell in the field, from saltwater corrosion to hard use on tough materials. The “best” steel is always a trade-off between edge retention, toughness, ease of sharpening, and corrosion resistance. What works for a chef won’t cut it for a survivalist. My goal is to cut through the marketing jargon and give you a practical, real-world perspective on what these steels actually do.

This guide is based on hands-on experience, not just lab data. We’ll look at five standout knife steels that are defining the market in 2025, from super-steels to trusted workhorses. I’ve included simple steel charts to compare their key properties at a glance. Whether you’re a professional or an enthusiast, understanding these options will help you make a smart investment. Let’s get straight into the five best knife steels you should consider for your next blade.

Top 5 Best Knife Steels for 2025

- Benchmade Bugout CPM-CruWear

- Spyderco Paramilitary 2 CPM-S45VN

- Chris Reeve Sebenza 31 Magnacut

- Zero Tolerance ZT 0562 CPM-20CV

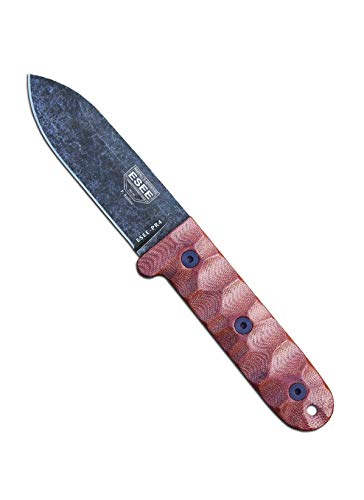

- ESEE Knives PR4 1095 Steel

Benchmade Bugout CPM-CruWear

CPM-CruWear is a high-end tool steel that strikes a fantastic balance. It offers the exceptional toughness of steels like 3V but with much better wear resistance. In practical terms, this means the edge is less likely to chip or roll under heavy impact, like prying or batoning, while still holding a sharp edge for a good long time. It’s a powder metallurgy steel, so the grain structure is very fine, allowing it to take a screaming sharp edge. I’ve used CruWear in wet, humid conditions, and while it’s not stainless, its corrosion resistance is better than many other tool steels, making it a solid choice for a hard-use folder or fixed blade that sees varied environments.

The Benchmade Bugout is a brilliant platform for this steel. The knife is famously lightweight and slim, making it an easy carry. Pairing that design with the robust nature of CruWear creates a tool that feels like a feather in your pocket but performs like a workhorse when you need it. It sharpens up relatively easily for a steel of its performance level, which is a huge plus for field maintenance. If you want a do-it-all EDC knife that can handle unexpected hard use without being a brick in your pocket, this combination is hard to beat.

Pros

- Excellent toughness for resisting chips and damage.

- Very good wear resistance and edge retention.

- Surprisingly good corrosion resistance for a tool steel.

Cons

- Not fully stainless; requires some maintenance.

- Can be more expensive than common stainless options.

Spyderco Paramilitary 2 CPM-S45VN

CPM-S45VN is the refined successor to the legendary S30V. Spyderco worked directly with Crucible Industries to develop this steel, aiming to improve toughness and corrosion resistance without sacrificing the excellent edge retention S30V is known for. In my use, it hits the mark perfectly. The edge is incredibly stable and resist chipping even during fine tip work or cutting abrasive materials. For a high-hardness stainless steel, it’s also remarkably easy to sharpen, which makes it a great choice for users who like to maintain their own edges.

The Spyderco Paramilitary 2 is arguably one of the most popular and well-designed folding knives ever made. Its ergonomics, compression lock, and one-handed operation are nearly perfect. Putting S45VN into this platform creates an EDC knife that is ready for anything. It holds an edge through weeks of daily cutting tasks, from cardboard to rope, and shows very little wear. The corrosion resistance is top-notch, so you don’t have to worry about sweat or rain. This is a set-it-and-forget-it steel on a top-tier platform.

Pros

- Superior edge retention and stability compared to S30V.

- Enhanced toughness and corrosion resistance.

- Relatively easy to sharpen for its performance class.

Cons

- Premium steel comes with a premium price tag.

- May be overkill for very light-duty users.

Chris Reeve Sebenza 31 Magnacut

Magnacut is the new king of stainless steels, and it’s living up to the hype. Developed by metallurgist Dr. Larrin Thomas, it was designed to be the ultimate all-rounder. It offers corrosion resistance on par with LC200N or H1, toughness similar to CruWear, and wear resistance that challenges S30V. This “balanced triangle” of properties means there are almost no compromises. In the field, this translates to a blade that shrugs off saltwater, won’t chip under stress, and holds a working edge for an impressively long time.

There is no better showcase for Magnacut than the Chris Reeve Sebenza 31. The Sebenza is the benchmark for precision folding knives, known for its flawless fit and finish. The combination of this legendary build quality with the revolutionary performance of Magnacut creates what many consider the perfect high-end EDC knife. It’s an investment, but you’re getting a tool that excels in every measurable category. If you demand the absolute best and want a knife that will last a lifetime with minimal fuss, this is the one.

Pros

- Unmatched balance of toughness, edge retention, and corrosion resistance.

- Extremely high corrosion resistance, ideal for marine environments.

- Performs excellently across a wide range of hardness levels.

Cons

- Extremely high cost, often found only on premium knives.

- Still a relatively new steel, so fewer knife models available.

Zero Tolerance ZT 0562 CPM-20CV

CPM-20CV is Crucible’s version of the super-steel Bohler M390. It’s a high-carbon, high-chromium steel loaded with vanadium carbides, giving it phenomenal wear resistance. In simple terms, this steel just doesn’t want to get dull. It will slice through miles of cardboard, plastic straps, and rope before needing a touch-up. Its corrosion resistance is also excellent, making it a low-maintenance option for everyday carry. The trade-off is that it can be a bit chippy if the edge is ground too thin, and it requires good sharpening equipment to bring back once it’s dull.

The Zero Tolerance 0562 is a tank of a folder that complements the 20CV steel perfectly. It’s built with a robust frame lock, smooth ball-bearing pivot, and overbuilt handles. This knife can handle hard use that would make other folders fail. The combination of the ultra-wear-resistant 20CV steel and the bullet-proof construction makes the ZT 0562 a go-to for anyone who needs a folding knife that performs like a small fixed blade. It’s not a light carry, but the confidence it inspires is worth the pocket space.

Pros

- Exceptional wear resistance and edge holding.

- Very high corrosion resistance.

- Ideal for cutting abrasive materials.

Cons

- Can be brittle if not heat-treated properly.

- Difficult to sharpen without diamond stones.

ESEE Knives PR4 1095 Steel

Never count out the classics. 1095 carbon steel is one of the oldest and most proven knife steels in the world. Its biggest strength is its incredible toughness. You can baton, pry, and abuse a 1095 blade, and it’s far more likely to bend than to snap. This makes it the gold standard for survival knives and hard-use fixed blades. It’s also very easy to sharpen, even in the field on a simple stone. The major downside is its lack of chromium, meaning it will rust quickly if not properly maintained.

The ESEE PR4 is a no-nonsense fixed blade designed by a survival instructor. It’s a tool meant to be used hard. ESEE’s heat treatment of 1095 is legendary, giving it a perfect balance of hardness and toughness. The knife comes with a durable powder coat to help mitigate corrosion. For a knife you’re betting your life on in the wilderness, where extreme toughness and easy field maintenance are paramount, 1095 is still a fantastic choice. It’s a humble steel, but it gets the job done when failure is not an option.

Pros

- Superior toughness and impact resistance.

- Very easy to sharpen to a sharp edge.

- Affordable and widely available.

Cons

- Very low corrosion resistance; requires constant care.

- Lower edge retention compared to modern steels.

5 Best Knife Steels in 2025 (Steel Charts & Practical Guide by a Marine)

Choosing a knife isn’t just about the shape; it’s about the steel. I’ve relied on my gear in some tough spots, and the wrong steel can fail when you need it most. Forget the marketing hype. We’re going to look at real-world performance: edge retention (how long it stays sharp), toughness (resistance to chipping), and corrosion resistance. Here are my top five knife steels for 2025.

First up is CPM MagnaCut. This is the modern all-rounder. For years, you had to pick two: toughness, edge retention, or corrosion resistance. MagnaCut gives you all three at an elite level. It’s a powder metallurgy steel that holds a scary-sharp edge and is surprisingly tough for its hardness. If you need one knife for everything, from saltwater environments to hard-use tasks, this is your top contender.

Next is CPM Cru-Wear. This is my go-to for a tough, hard-use blade. It’s a high-wear resistance steel with fantastic toughness, meaning it can take a beating without chipping or rolling. It’s not stainless, so it will develop a patina, but that’s a small price to pay for its durability. Think of it as a modern super-steel with the soul of an old-school tool steel. Perfect for a survival knife or a hard-working fixed blade.

For those who need maximum stainlessness, LC200N is the answer. This is a nitrogen-based steel that is nearly impervious to rust. I’ve used knives in this steel on boats and in humid environments for weeks with zero maintenance. Its edge retention is good, not great, but its incredible corrosion resistance makes it a specialist for sailors, fishermen, or anyone who works around water.

We can’t ignore the classic, CPM S35VN. This steel has been a benchmark for over a decade for a reason. It offers a great balance of good edge retention, decent toughness, and solid corrosion resistance. It’s widely available, easier for manufacturers to work with, and often found on knives at a more accessible price point than MagnaCut. It’s a proven, reliable performer.

Finally, for pure edge retention, look at CPM S90V. This steel is packed with vanadium carbides, making it exceptionally wear-resistant. It will hold an edge through a mountain of cutting tasks. The trade-off is that it can be more brittle (lower toughness) and is a bear to sharpen without the right tools. This is a steel for the user who prioritizes long-lasting sharpness above all else and doesn’t mind a sharpening challenge.

FAQ

What is the most important property in a knife steel?

There isn’t one single “most important” property; it depends entirely on your use. It’s a balance. If you’re a sailor, corrosion resistance is your top priority. If you’re batoning wood with a survival knife, toughness is critical to prevent chipping. For someone who processes a lot of cardboard or rope, edge retention might be key. My guide on the 5 Best Knife Steels in 2025 (Steel Charts & Practical Guide by a Marine) groups steels by their strengths to help you decide what balance works for your needs.

Is a harder steel always a better steel?

No, not at all. Hardness (measured on the Rockwell C scale, or HRC) relates directly to edge retention. A harder steel will generally stay sharp longer. However, as hardness increases, toughness usually decreases. A very hard steel is more prone to chipping if you twist the blade or hit a hard object. A slightly softer, tougher steel might roll its edge instead of chipping, which is much easier to fix in the field. It’s a trade-off.

What does “powder metallurgy” mean and why does it matter?

Powder metallurgy (seen in steels with the CPM or similar prefixes) is a manufacturing process where the molten steel is atomized into a fine powder and then solidified under heat and pressure. This creates a much more uniform and fine-grained steel structure. The result is a steel that can have a higher concentration of wear-resistant carbides without becoming brittle. In simple terms, it allows for better performance across the board—better edge retention and higher toughness simultaneously.

How does corrosion resistance affect my knife?

Corrosion resistance is the steel’s ability to resist rust and pitting. Low corrosion resistance (in non-stainless steels like Cru-Wear or 1095) means you must be diligent about cleaning, drying, and oiling your blade, especially after use in wet or humid conditions, or around acids. High corrosion resistance (in steels like LC200N or MagnaCut) means the knife is far more forgiving and requires minimal maintenance. This is a huge factor for everyday carry in humid climates or for marine use.

Which of these steels is the easiest to sharpen?

Generally, simpler steels with fewer complex carbides are easier to sharpen. Among the high-performance steels listed, Cru-Wear and MagnaCut are known for being relatively straightforward to sharpen compared to something like S90V. S90V contains a high volume of very hard vanadium carbides, which require diamond or CBN sharpening stones to cut effectively. If you’re new to sharpening, a steel like S35VN offers a good balance of performance and sharpenability.